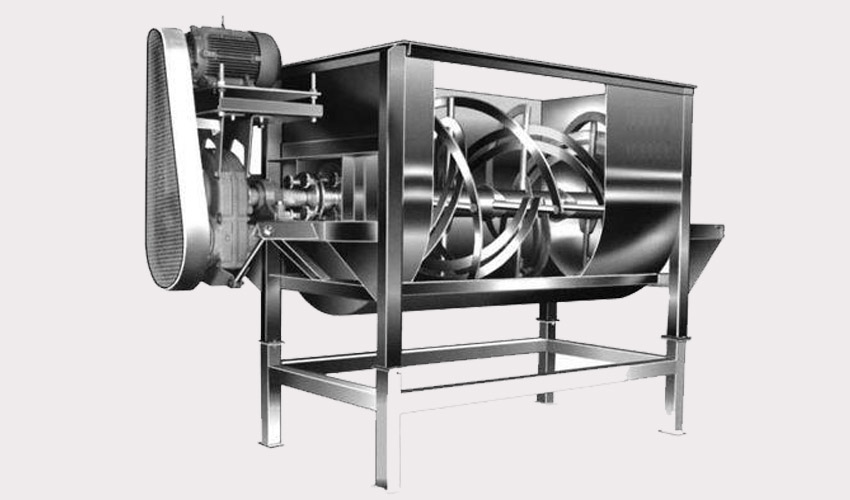

Ribbon Blender

Ribbon Blender that we offer is globally appreciated for its superior technology & acceptable price range. It is widely used for mixing dry powder, which is usually a free flowing solid substance. Our ribbon blender fabricated in well equipped infrastructure is definitely worth buying & a very profitable industrial investment. These are proven agitator construction based blenders that help in providing triple mixing action, which ensures efficient blending. These blenders are precisely designed to impart the complete linear and radial motion for effectively mixing the homogenous material. We offer them in different configurations and can be customized as per the preferences. With an experience of over two decades in handling the various process applications in Dyes, Intermediates, Pigments, Pesticides, Fine Chemicals, Rubber Chemicals, Bulk Drugs, API and Nutraceuticals.

Industrial Ribbon Blender Mixer

The Industrial Ribbon Blender Mixer is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximately two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container.

The complete assembly is mounted on a MS/ SS structureThe complete assembly is mounted on a MS/ SS structure

The material is moved from side of the trough to the centre and vice versa resulting in quick & homogeneous mixing

Double Helical ribbon configuration also brings material towards central bottom outlet while discharging

A specially designed valve is provided at the center or butterfly valve for discharge

Blending is achieved in semi-fluidized state in the upper zone of the trough when used for fine powders

Ribbon Blender Machine can be provided with spray nozzles with pressure spraying system for spraying additives in blenders

Salient features

All contact parts in SS 304/ SS 316 quality

Ribbon Blender comes in Standard and GMP models specially designed flush type outlet valve or

Butterfly valve (optional)

Top cover with acrylic sheet

The cover is connected to limit switch for the safety purpose

Machine automatically stops as soon as the cover is opened during the operation

Shaft sealing at inside and out side with Teflon bush and SS stuffing box

Solid stainless steel end covers and frame work on the trough in even standard models for long trouble

free life of the Ribbon Blender Machine.

Process control panel with batch timer and cyclic timer for reverse & forward direction of ribbon

Spray nozzles with pressure spraying system for spraying additives in blenders during process

Cooling or heating jacket can be provided for special uses such as crystallizing or drying

Variable speed drive and two speed motors can be provided on demand