Working: 8.00am - 5.00pm

Working: 8.00am - 5.00pm

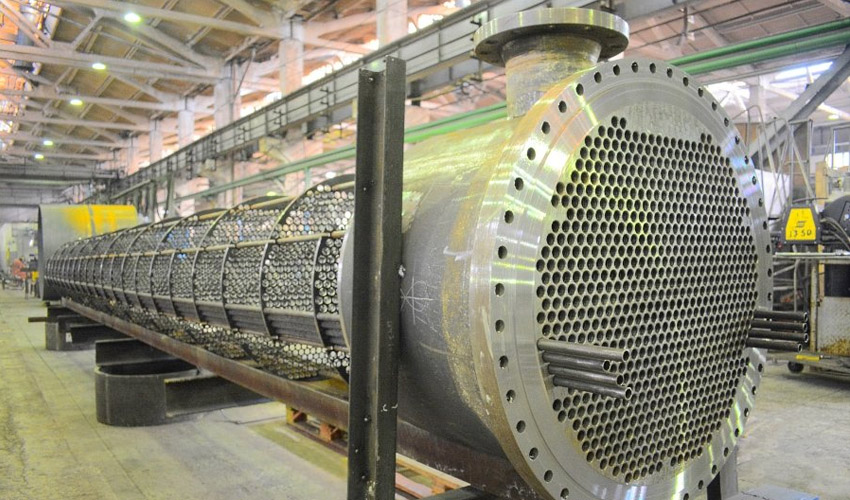

Air Cooled compressed air after coolers cool the compressed air with atmospheric air. The compressed air is cooled to approximately 9◦C, above ambient temperature. This substantially reduces the water and other contaminants in your air supply, as water will be reduce by ½ for every 20 degree reduction in temperature. This moisture is then removed from the system with a separator and drain assembly. A sufficient capacity after cooler can take up to 80% of the moisture present in the compressed air. Air Cooled Aftercooler is used in food, mining and construction industry. It uses either air or water and is an effective means of removing moisture from compressed air.

The BL Series is a complete aftercooler package designed to work on most models of rotary and piston air compressors. To select the appropriate model, simply determine compressor horsepower, and select the model from the chart.

A cooler/separator is required to reduce the temperatures and discharge the condensed moisture. By using this Blastpak System increase production and reduce downtime and maintenance cost. Moisture in the compressed air system contaminates both controls and abrasive causing the abrasive to bridge and not flow property. This system effectively provide cooler, cleaner and dry air to your blast pots with negligible drop in pressure. Two system types are available to meet your specific requirements after coolers and air dryers. Our range is fabricated from various material, ranging from aluminium to walnuts and from steel to specially formulated plasticized PVC compounds. The products available with us have been widely appreciated by customers based in India as well as offshore.