Working: 8.00am - 5.00pm

Working: 8.00am - 5.00pm

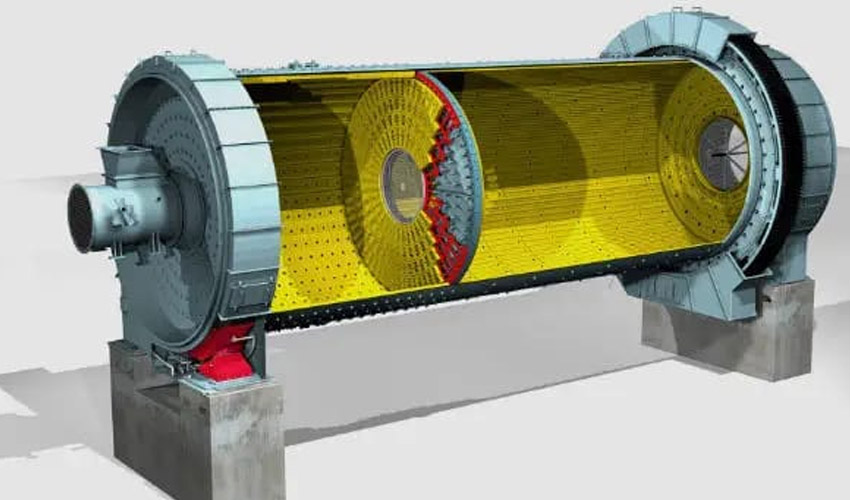

Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods), the product to be ground is added and the cylinder is put into rotation via an external drive causing the media to roll, slide and cascade. Lifting baffles are supplied to prevent the outer layer of media to simply roll around the cylinder.

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills.

At Rudra Industries we offer a variety of drive options to suit your needs:

Mill cylinders are typically supplied with a cooling jacket on their cylindrical portion for temperature control, especially when processing temperature-sensitive materials. For extreme temperatures, the ends of the cylinder can also be furnished with cooling apparatus. For discharge of the product on wet grinding processes we offer our standard media retention grate along with an adequate size discharge valve. For discharge of the product on dry grinding processes we offer our dry media retention grate and housing.